Recently added item(s)

Easy-to-use technology

FOR OPTIMIZED WORKFLOW

OPERATING SEQUENCE

Loading

The microwave cavity has a volume of over 70 liters, the largest currently available. Therefore, digestion rotors with more sample places can be accommodated, incresing both productivity and sample throughput. Secondly, it improves the inherently safety because a larger cavity contains gases escaping from vessels in a more efficient way, in case of a sudden over pressurization.

Heating and cooling

The ETHOS UP is equipped with two 950 Watt magnetrons for a total of 1900 Watt. The system additionally employs a rotating diffuser that evenly distributes the microwaves throughout the cavity. High power coupled with this diffuser enable very fast heating of high throughput rotors and the complete digestion of the most difficult samples.

Closing and pressurizing

For additional safety, the ETHOS UP features a full stainless steel door with an innovative opening and self-resealing mechanism. Should there be a sudden over pressurization of the cavity, the door slightly opens for rapid and safe pressure release and the microwave power is instantaneously cut off. Immediately afterwards, the door is pulled back, resealing the microwave cavity.

Pressure release and opening

The ETHOS UP integrates the Milestone safeVIEW, a high definition digital camera interfaced with the instrument terminal. It allows the chemist to monitor the progress of the digestion whilst being fully protected by the instrument’s all-stainless steel door. A video of the entire run is shown in real time.

DIGESTION VIALS

The ultraWAVE rack configurations include 4, 5, 8, 15, 19, 22 and 26 position and combinations thereof. Vials are available in TFM, quartz or disposable glass, and are fitted with loose TFM caps to ensure pressure equalization. Unlike conventional microwave digestion systems, no vessel assembly or disassembly is required. The use of disposable glass vials eliminates the cleaning step, further enhancing the lab’s workflow. The fast assembly of the vials, the automatic closing and opening cut the handling time, reducing the labour cost up to 50%.

SAFETY

Like all Milestone products, the ultraWAVE has been designed with operator safety of paramount importance: it has been developed for being used with any acid or combination thereof, and every single reactor is tested at a pressure up to 330 bar. A thick acrylic shield surrounds the working area, and runs cannot be started unless the chamber clamps are in correct position. Temperature and pressure are monitored 20 times/sec, automatically adjusting microwave power to control even highly exothermic reactions.

Any sample, any time

THE BENEFITS OF SRC TECHNOLOGY

ONE METHOD FOR ALL SAMPLES

Any combination of sample types (food, environmental, polymer, cosmetic, pharmaceutical, geological, chemical, and petrochemical) can be digested simultaneously; no need to batch samples into identical types. No method development is needed, as the same method can be used for nearly any sample. And for the first time, blanks and reference standards of any matrix can be digested alongside samples, enabling true in-run digestion quality control.

SUPERIOR DIGESTION QUALITY

Operating up to 199 bar pressure and 300°C temperature, the ultraWAVE enables the complete digestion of extremely difficult samples and of large amounts of organics, outperforming any other microwave digestion system. Unlike conventional microwave digestion systems, every sample is under direct temperature and pressure control, so there is no need to rely on a reference vessel or to an indirect control such as infrared temperature sensors.

The ultraWAVE reaches high temperatures faster, cools faster (10 minutes from 200°C to room temperature), and is capable of higher pressure and temperature than any other system. The ultraWAVE does not suffer of any cross contamination among samples. Blanks are significantly lower than with conventional microwaves, since less acid is used and vials have a much less surface in contact with the analytical solution.

Efficient and Cost-Effective

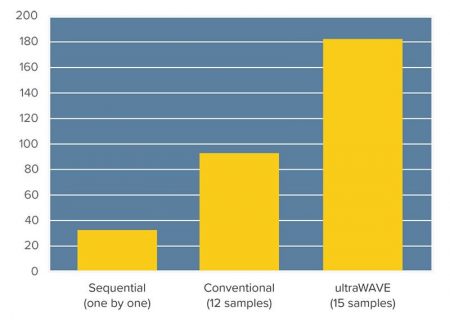

Typical sample turnaround time (number of samples in 8 hours).

Compared to any other conventional microwave digestion systems, the ultraWAVE is significantly easier to use, thus dramatically improving the laboratory work flow. Up to 26 samples are processed in 45 minutes start to finish. Ease to say that the ultraWAVE sample throughput is far better than any other microwave systems.

All samples are processed in a single run at the same temperature and pressure, eliminating the need to run multiple digestion cycles for different samples or matrices. The use of disposable glass vials eliminates the cleaning step, further enhancing the ultraWAVE productivity.

Typical sample turnaround time (number of samples in 8 hours).

Compared to any other conventional microwave digestion systems, the ultraWAVE is significantly easier to use, thus dramatically improving the laboratory work flow. Up to 26 samples are processed in 45 minutes start to finish. Ease to say that the ultraWAVE sample throughput is far better than any other microwave systems.

All samples are processed in a single run at the same temperature and pressure, eliminating the need to run multiple digestion cycles for different samples or matrices. The use of disposable glass vials eliminates the cleaning step, further enhancing the ultraWAVE productivity.

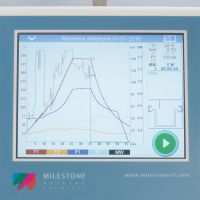

SMART SOFTWARE

Designed around you

The ultraWAVE is controlled via a compact external terminal with an easy-to-read, bright, full-color, touchscreen display. Multiple USB and Ethernet ports are provided, for interfacing the instrument to external devices and to the local laboratory network. The terminal runs the Milestone easyWAVE, a completely new user-friendly, icon-driven, and multi-language software. Just recall a previously stored method or create a new one; press the Start icon and the system will automatically follow the user defined temperature profile using a sophisticated PID algorithm.

Hundreds of applications, including all US EPA methods, are preloaded, eliminating any need for method development.

Need to fulfill regulatory requirements?

The Milestone Validation Packages include several protocols in order to fulfill regulatory requirements, such as the Good Manufacturing Practice (GMP) guidelines that, along with our superior support and expertise, will be by your side throughout the whole process. Our experts will support you with the right confi guration, with a dedicated procedure for your samples, with a demonstration of the system’s capabilities and with a complete validation package that includes: DQ (Design Qualification), IQ (Installation Qualification), OQ (Operational Qualification), PQ (Performance Qualification) and the requalification. All the tests carried out by our service engineers are guaranteed by certified test equipment, providing high accuracy and meeting all the regulatory requirements. Our software is fully compliant with the FDA regulation 21 CFR part 11, with an exhaustive audit trail for complete traceability. The MVP is one of the multiple services offered by Milestone to ensure the highest industry standards in customer support.