Recently added item(s)

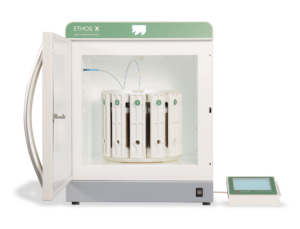

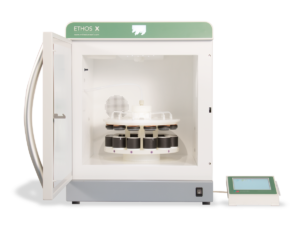

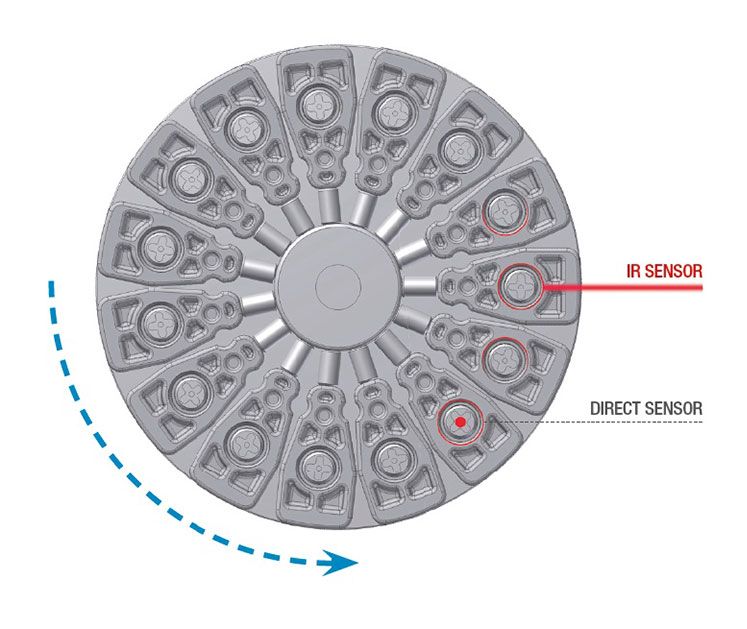

ETHOS X

Microwave Extraction System for GC and HPLC Analysis

Samples submitted for GC and HPLC analysis require pre-treatment.

The fundamental step in sample pretreatment is compound extraction from the sample matrix. This is the least evolved -many people still use the Soxhlet extraction method invented in 1879-, most error-prone step in the overall analytical procedure.