Recently added item(s)

New horizons in Microwave Chemical Synthesis

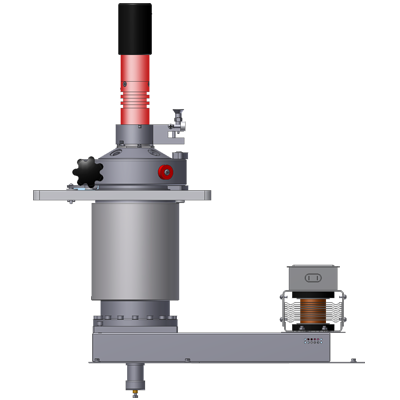

SRC TECHNOLOGY

Milestone’s unique Single Reaction Chamber (SRC) technology overcomes the limitations of current microwave synthesis instrumentation. A PTFE lined, 1 L stainless steel reaction chamber serves also as microwave cavity. The design of the microwave source perfectly match the cavity shape for optimum microwave distribution and fast, even heating. The chamber is prepressurized with gas to prevent boiling of the solution, and is equipped with mechanical and magnetic stirrers. The microwave cavity is water cooled, which greatly reduces reaction cooling time and increases productivity.

SAFETY

Like all Milestone products, the synthWAVE has been designed with operator safety of paramount importance. A thick acrylic shield surrounds the work area, and it lowers into position automatically as the chamber is closed. A microwave run cannot be started unless the chamber clamp is in position, and the clamp cannot be released until the chamber is cool, and pressure has been released. The PID controller continuously monitors temperature and pressure, instantaneously adjusting microwave power to control even highly exothermic reactions.

SOFTWARE-CONTROLLED STIRRER

The synthWAVE features a powerful stirrer, which ensures vigorous stirring in the 1L PTFE vessel, or in all vials whenever a rack is used, thus assuring reliable and consistent results.

HOW THE synthWAVE WORKS

RACK AND VIALS

Reactions can be carried out directly in the 1L PTFE vessel, or in multiple vials. Vials are available in glass (disposable), quartz or PTFE, fitted with loose PTFE caps to ensure pressure equalization. Available rack configurations include 4, 5, 15 and 22 positions. The synthWAVE sample racks fit easily on a balance, so reagents can be weighed directly into vials already loaded into a rack. No vessel assembly or disassembly is required, and with the disposable glass vials, no cleaning step is needed, greatly increasing work efficiency.

FASTER SCREENING

Multiple reactions are carried out simultaneously under exactly the same temperature and pressure conditions – even using different solvents. Quickly and easily evaluation of different catalysts, solvents and reaction conditions.

OPERATE IN MODIFIED CONDITIONS

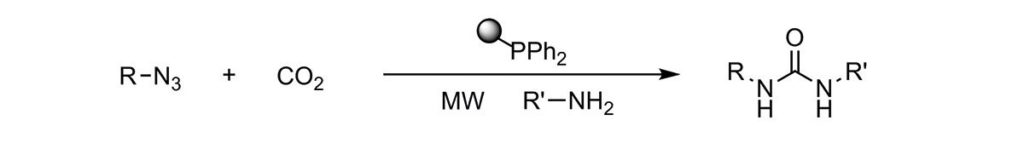

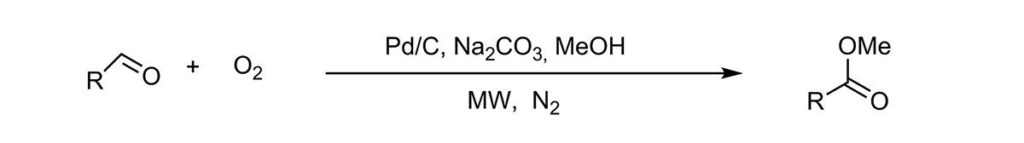

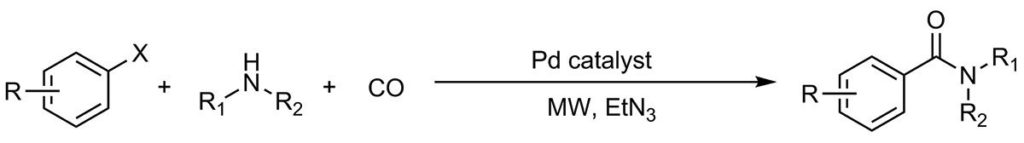

Simply add an inert gas to achieve an inert environment. Add hydrogen or oxygen to produce a reducing or oxidizing atmosphere respectively. Speed up reactions with gas molecule insertion using gases such as CO or CO2.

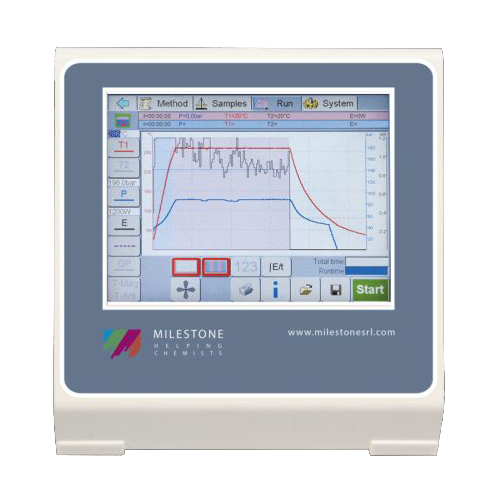

easyCONTROL

Operating Software

synthWAVE is controlled via a compact terminal with an easy-to-read, bright, fullcolour, touchscreen display. The terminal is provided with multiple USB and Ethernet ports for interfacing the instrument to external devices and to the local laboratory network.

The terminal runs a completely new user-friendly, icon-driven, multi-language software to provide easy control of the microwave run. Simply recall a previously stored method or create a new one, press ‘START’ and the system will automatically follow the user defined temperature utilizing a sophisticated PID algorithm. Furthermore, all reaction parameters can be modify “on-the-fly”, thus assuring the highest flexibility of operation.

APPLICATIONS

- Oxidations and Reductions

- Esterification & Ammidation

- Coating

- Polymerization

- Nanoparticles preparation

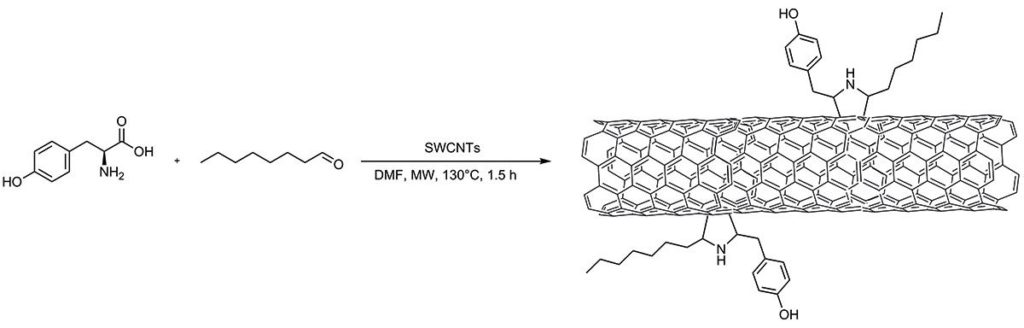

- Modification of carbon nanotubes

- Reactions with sensitive reagents and materials

- Desulphurization

- Cycloadditions

- Reagents and Materials

- Click chemistry

- Gas insertion

- Multicomponent reactions

- Dechlorination

- Subcritical fluids extracion

- Stereoselective transformations

- C-C, C-X Couplings