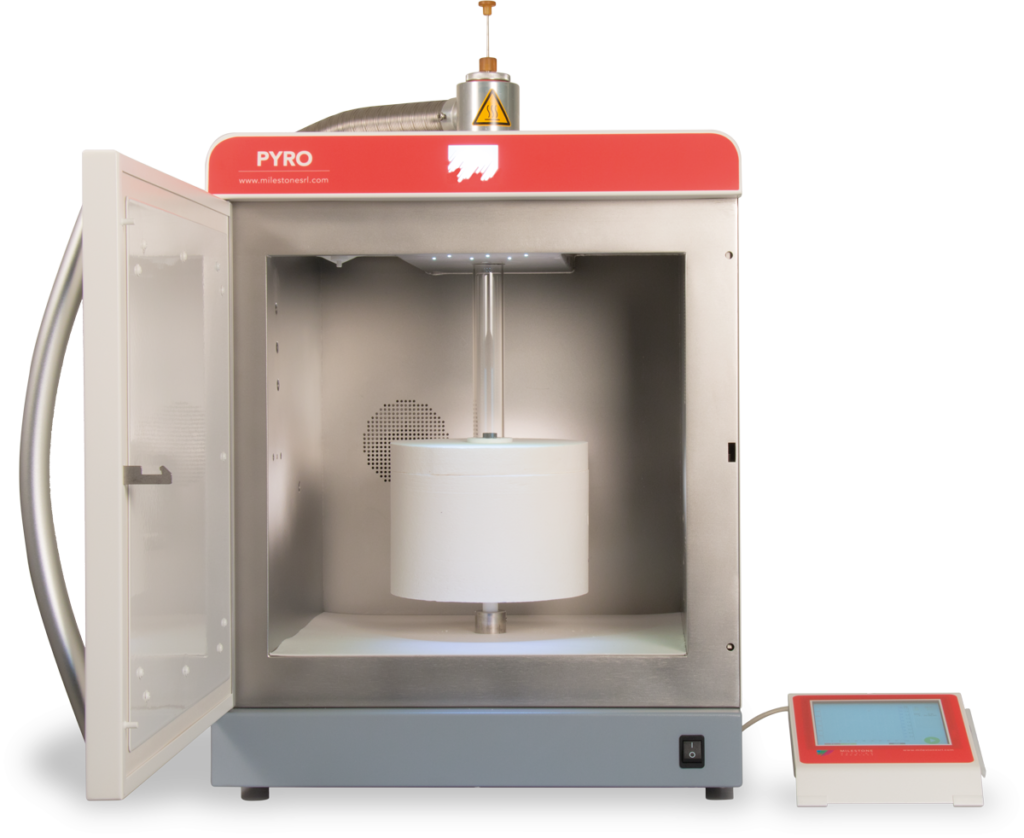

PYRO HIGH THROUGHPUT

Advanced Microwave Muffle Furnace

The new Milestone PYRO is an advanced microwave muffle furnace ashing system of new generation. PYRO perfectly suits several applications including ashing, sulfated ashing, loss on ignition (LOI), residue on ignition (ROI), fusion and generally all high-temperature reactions under controlled conditions.