Recently added item(s)

Rugged and durable construction

STANDARD 1 YEAR WARRANTY!

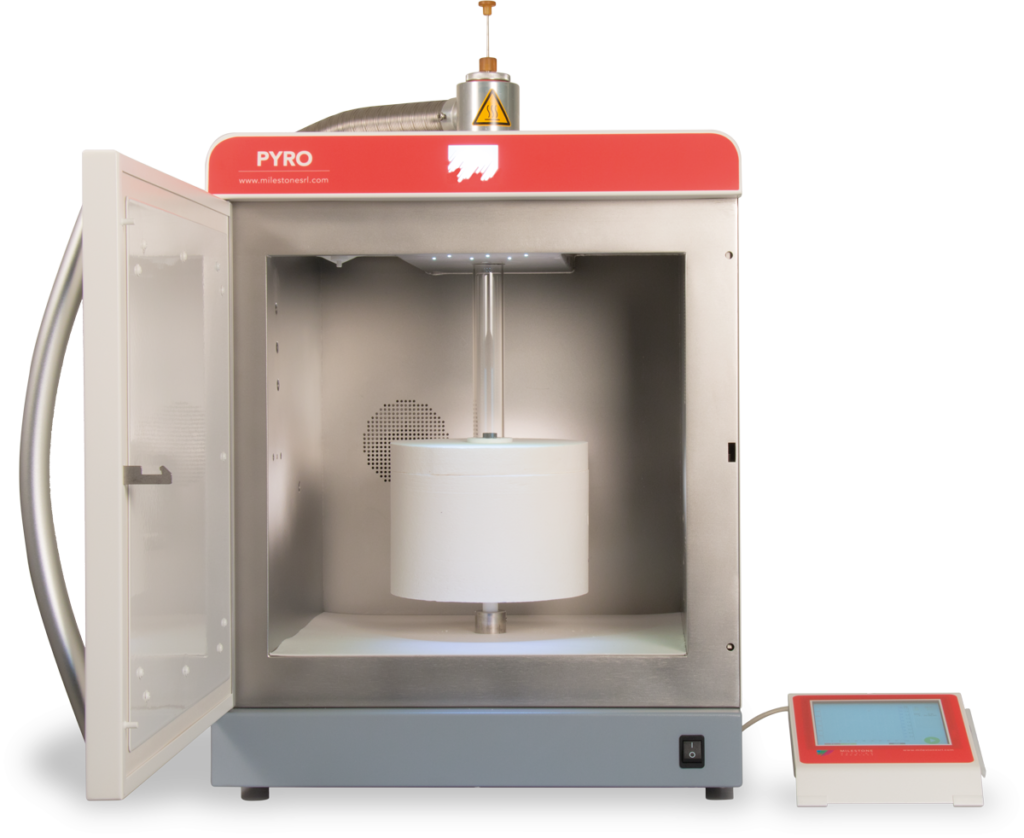

While ashing is a relatively simple process, conventional muffle furnaces are often inefficient, leading to tedious and time-consuming procedures. The advent of microwave technology for dry ashing applications has represented a breakthrough in the process and quality control of samples like polymers, petroleum, food and feeds, pulp paper and pharmaceuticals.

Ultrafast Heating

Fast heating – 8 minutes only from room temperature to 1.000°C! This eliminates the necessity of running the system overnight, and avoids the lengthy heat up times associated with electrical resistance furnaces, dramatically lowering average power costs.

High Sample Throughput

High sample throughput – up to 24 samples simultaneously, thanks to the PYRO’s extremely large working cavity area

Three Different Setup

Three interchangeable configurations for several applications.

LARGEST MICROWAVE CAVITY

Equipped with a full stainless steel door, the new Milestone PYRO microwave cavity has a volume in excess of 70 liters, thus allowing the use of a large muffle which in turn enhances the sample throughput. Additionally, a large cavity ensures that the outer temperature of the PYRO remains very low, even when the inner temperature of the furnace is in excess of 1.000°C.

TEMPERATURE CONTROL

The new Milestone PYRO is equipped with the most advanced yet easy to use temperature sensors for complete control of the ashing conditions. These NIST-traceable sensors allow rapid verification and calibration of the furnace temperature for ISO and GLP procedures.

HIGHEST POWER

The PYRO is equipped with two 950 Watt magnetrons for a total of 1900 Watt making it the most powerful microwave muffle furnace system available in the market. The system additionally employs a rotating diffuser that evenly distributes the microwaves throughout the cavity, assuring a uniform temperature is achieved inside the furnace.

METHODS COMPLIANCE

The PYRO meets or exceeds the equipment requirements for electrically heated furnaces in the following methods: ASTM, USP ROI 281 and LOI 733, AOAC, FDA, ISO and DIN. It also meets or exceeds the requirements for applications listing a microwave heated furnace in the following methods: ASTM D5630-94 and ASTM D1506-94b.

A dedicated configuration for every need

The PYRO is available in 3 different and interchangeable configurations: ultrafast heating setup, high sample throughput setup and sulfated ashing setup; it is therefore the most flexible and adaptable microwave muffle furnace available in the market.

Sulphated Ashing Set-up

Ashing of pharmaceutical, polymers, and food samples often involves the use of sulfuric acid. Hot sulfuric acid vapors are hazardous to analysts and corrosive to equipment. Additionally, sulfate ashing methods are labor-intensive and time-consuming, requiring manual fuming of the acid and 8-12 hours to be completed. To overcome these issues, Milestone has developed the Sulfated Ashing Setup.

This PYRO configuration enables the analysts to add sulfuric acid to the samples and directly place crucibles into the microwave muffle furnace, without a preliminary charring step. Tedious handling of samples and operator exposure to acid fumes are totally eliminated. The system is designed for complete operator safety, and performs the complete sulfate ashing procedure in just 1 hour. Sulfuric acid fumes released from crucibles are continuously exhausted passing through a quartz tube and an air-cooled quartz collection vessel outside the unit. The fumes are finally contained and neutralized in a dedicated acid scrubber module.

easyCONTROL

Operating Software

The PYRO is controlled via a compact terminal with an easy-to-read, bright, full-colour, touchscreen display. The terminal is provided with multiple USB and Ethernet ports for interfacing the instrument to external devices and to the local laboratory network. The terminal runs a completely new user-friendly, icon-driven, multi-language software to provide easy control of the microwave run. Simply recall a previously stored method or create a new one, press ‘START’ and the system will automatically follow the user defined temperature utilizing a sophisticated PID algorithm.

Several applications, including all ASTM, USP, SEMI and ISO methods, are preloaded in the PYRO terminal. There is no need to input the number of crucibles or sample weights, as the software will automatically regulate the microwave power according to the temperature profile desired.

This assures a consistent quality of the results and simplifies the use of the instrument.

Over 90% Time Saving

| SAMPLE | TEMPERATURE (°C) | TIME (MINUTES) |

|---|---|---|

| Pet Food | 575 | 20 |

| Milk Powder | 550 | 20 |

| Wheat Flour | 900 | 50 |

| Polypropylene | 650 | 20 |

| PVC | 900 | 15 |

| Coal | 750 | 20 |

| Heavy Oil | 550 | 45 |

| Rubber Tyre | 550 | 45 |