Recently added item(s)

Rugged, reliable microwave platform

While other manufacturers use molded plastic, Milestone uses 18/8 stainless steel construction throughout which creates the most durable, reliable, and safe microwave system available.

THE LARGEST STAINLESS-STEEL MICROWAVE CAVITY

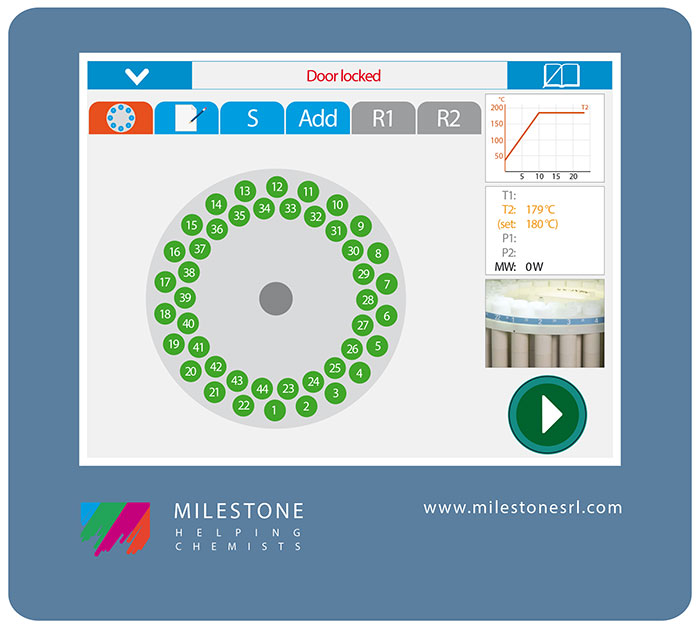

The microwave cavity has a volume of over 70 liters, the largest currently available. Therefore, digestion rotors with more sample places can be accommodated, incresing both productivity and sample throughput. Secondly, it improves the inherently safety because a larger cavity contains gases escaping from vessels in a more efficient way, in case of a sudden over pressurization.

THE MOST POWERFUL MICROWAVE DIGESTER

The ETHOS UP is equipped with two 950 Watt magnetrons for a total of 1900 Watt. The system additionally employs a rotating diffuser that evenly distributes the microwaves throughout the cavity. High power coupled with this diffuser enable very fast heating of high throughput rotors and the complete digestion of the most difficult samples.

PRESSURE-RESPONSIVE DOOR FOR MAX SAFETY

For additional safety, the ETHOS UP features a full stainless steel door with an innovative opening and self-resealing mechanism. Should there be a sudden over pressurization of the cavity, the door slightly opens for rapid and safe pressure release and the microwave power is instantaneously cut off. Immediately afterwards, the door is pulled back, resealing the microwave cavity.

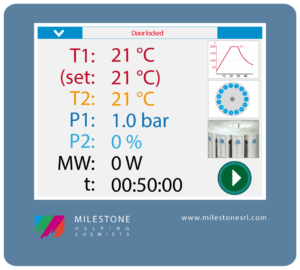

LIVE MONITORING WITH MILESTONE SafeVIEW

The ETHOS UP integrates the Milestone safeVIEW, a high definition digital camera interfaced with the instrument terminal. It allows the chemist to monitor the progress of the digestion whilst being fully protected by the instrument’s all-stainless steel door. A video of the entire run is shown in real time.

Sensor

For unparalleled digestion control

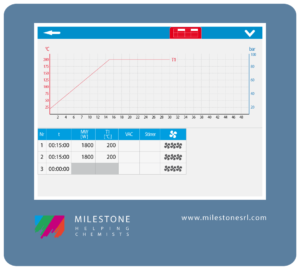

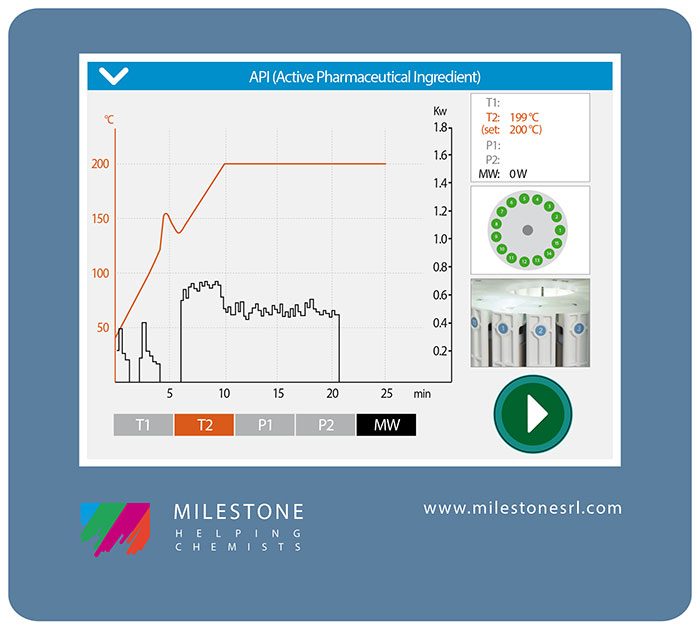

In a digestion process, the temperature controls the sample decomposition and directly affects digestion quality. Milestone pioneered the use of infrared sensors combined with an in-situ temperature sensor. Today, Milestone innovates again by combining all the benefits of in-situ and infrared sensors into the Milestone easyTEMP, a direct contactless temperature sensor.

Temperature control with easyTEMP

The easyTEMP contactless sensor directly controls the temperature of all samples and solutions, providing accurate temperature feedback to ensure complete digestion in all vessels with superior safety. This technology combines the fast and accurate reading of an in-situ temperature sensor with the flexibility of an infrared sensor.

The ETHOS UP software provides digestion history traceability and temperature measurement for every sample. Temperature diagrams and profiles are displayed in real-time, and can be saved on the ETHOS UP terminal.

In combination with our ‘vent-and-reseal’ vessel technology, these sensors ensure complete and safe digestions without any loss of volatile compounds.

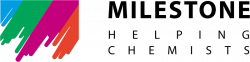

SMART SOFTWARE

To save your time

The ETHOS UP comes with a dedicated touch screen terminal with easyCONTROL software which provides full control of all digestion parameters, complete documentation and improves the overall procedure. Hundreds of applications, including all US EPA methods, are preloaded in the ETHOS UP terminal, virtually eliminating any need for method development. To further simplify the workflow in the lab the ETHOS UP is equipped with a backlit logo that indicates the actual status of the digestion process.

- Hundreds of methods factory stored

- Visual indication of temperature and pressure values

- Methods and runs printed or saved as PDF files

- Instrument's trail tracking (CFR-21 Part 11 compliance)

- Easy-to-read, bright, full-color, touchscreen display

- Icon-driven, multi-language software